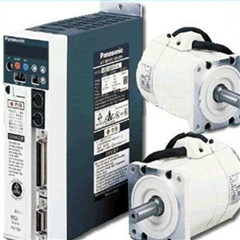

At present, the on-line

maintenance instrument can only carry out the on-line test and static

characteristic analysis of the devices on the servo driver circuit board,

whether it is completely repaired must go through the whole machine test and

inspection, therefore, the best way to check whether the power supply of the

equipment is supplied to the injection molding machine circuit board according

to the requirements.

[2] look first and then

measure.

Tools: multimeter and

magnifying glass. When holding a circuit board that needs to be repaired by a

servo driver https://www.plcdealer.com/panasonic-servo-drive-msda023a1a-expedited-shipping-original-new_p474.html, it is a good habit to visually test it, if necessary, use a

magnifying glass. The main reasons are as follows:

A, whether there is a broken

line;

B, whether the printed

circuit board connection line on the server circuit board has broken, adhesion,

etc.;

C, whether there is a disconnect phenomenon of discrete components such as resistance, electrolytic capacitance, inductor, diode, transistor https://www.plcdealer.com/mitsubishi-melsec-aj65vbts2-16t-transistor-module-cc-link-16-sink-spring-clamp_p652.html

D.Did anyone repaired the

servo driver? What components have you moved? Whether there are false welding,

leakage welding, insertion reverse and other operational errors;

E, After determining the

absence of the above conditions, use a multimeter to measure the resistancevalue between the power supply and the ground of the server circuit board at

first, if the resistance value is too small, only a few or more ohms,

indicating that there are components on the server circuit board that have been

broken through or partially broken down, we must take measures to find out the

broken components. The specific method need servo drive maintenance circuit

board power supply, with hands to touch the temperature of each device on the

server circuit board, feel hot will be the key suspect object.

F.If the resistance value is

normal, the purpose of measuring the resistance, diode, transistor, field

effect transistor, dialing switch and other discrete components on the board

with multimeter is to ensure that the measured components are normal first. The

maintenance reason of our servo driver is the problem can be

solved by multimeter should not be complicated.

[3] Easy first and then

difficult.

Servo driver maintenance

using circuit on-line maintenance instrument, electric soldering iron, marker.

In order to improve the test effect, some technical processing should be done

to the repaired board before the online function test of the server circuit board,

in order to weaken the negative influence of all kinds of interference on the

test process as much as possible.

The specific servo driver

maintenance measures are as follows: the preparation before the test will short

circuit the crystal oscillator, welding the next foot to open the circuit to

the large electrolytic capacitance, the charge and discharge of the capacitance

can bring interference also.

[4] external and then internal

Use tools: if the situation

permits, best to find the same good board as the servo drive maintenance board

as a reference,then use the two-rod VI curve scanning function to carry on the

good and bad contrast test to the two boards, the starting contrast point can

start from the port, and then from the table to the inside, especially the

capacitance comparison test which Can make up for the multimeter online

difficult to detect whether the leakage of the defect.

You can contact us any way that is convenient for you. We are available 24/7 via fax, email or telephone

Room 801, Yaojiangli No.165, Tong'an District, Xiamen China

+86 18046272706,+86 15395929858